Model X3 Air Cooled Mini Laser Welding Machine with Wire Feeder Portable Handheld Laser Welder

Working mode: continuous laser and pulsed laser

Can be equipped with a robotic arm

Wobble welding

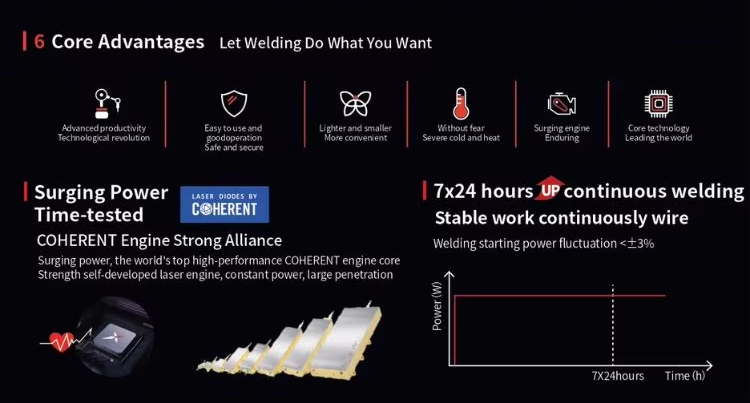

Big pump engine, surging power, globally leading semiconductor laser pump source in the industrial field

Strong air cooling, real-time welding without preheating

Maintain sufficient power margin at rated power output state

Industry leading optical technology and control solutions achieve high efficiency, low energy consumption, and deep welding seams

Global top high-performance chips ensure stable and reliable laser quality

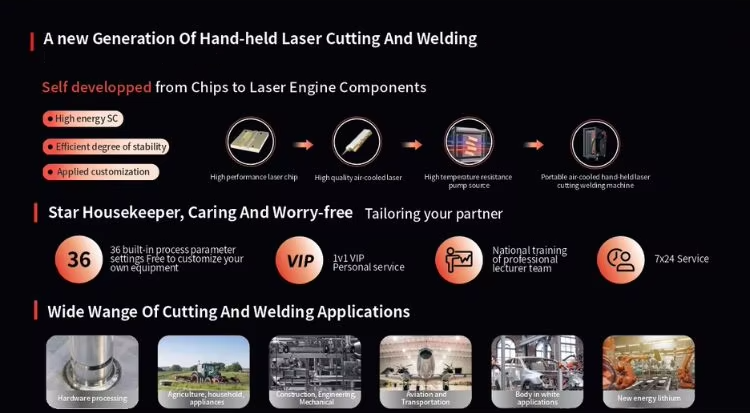

High quality pump source + High performance laser chips → Efficient heat sink to solve heat dissipation problems

Unlike traditional welding methods, portable air-cooled welding machines have a smaller volume and are more suitable for outdoor work. The grounding point does not need to be completely cleaned, and even beginners can reliably weld materials of different thicknesses and conductivity. In addition, the heat affected zone is greatly reduced, while also reducing the grinding and polishing required for traditional welding methods, thereby improving productivity, reducing waste, and lowering the cost of each workpiece.

Small laser welding machine, specialized for general workers without welding experience, with fast welding speed, firm welding seams, weight and volume better than water-cooled handheld laser welding machines, improving the mobility of the entire machine.

|

Model |

X3 |

X4 |

X4H |

X5 |

|

Center wavelength |

1080±10nm |

|||

|

FWHM spectral bandwidth |

<10nm |

|||

|

Divergence angle |

0.06NA |

|||

|

Light spot energy distribution |

Gaussian |

|||

|

Work mode |

CW & Pulse |

|||

|

Maximum modulation frequency |

5kHz |

10kHz |

10kHz |

10kHz |

|

Output power instability |

<3%(24 hours) |

<3%(24 hours) |

<3%(24 hours) |

<5%(24 hours) |

|

Power adjustment range |

10%-100% |

|||

|

Indicate laser parameters |

650nm≥1mW |

|||

|

Output fiber core diameter |

14μm |

14μm |

20μm |

20μm |

|

Armor cable fiber length |

5m |

5m |

5m |

5m/10m (Special custom) |

|

Output connector |

XphotonicsQBH |

|||

|

Fiber bending radius |

200mm |

200mm |

200mm |

300mm |

|

Input voltage |

Single phase 220V±10%; 50/60HZ |

|||

|

Power consumption |

≤10A 2200W |

≤14A 3000W |

≤19A 4500W |

≤19A 4500W |

|

Mechanical Dimensions |

420*255*550mm |

420*255*550mm |

525*255*620mm |

525*255*620mm |

|

N.W. |

25KG |

25KG |

41KG |

42KG |

Advantages of portable air-cooled laser welding machine:

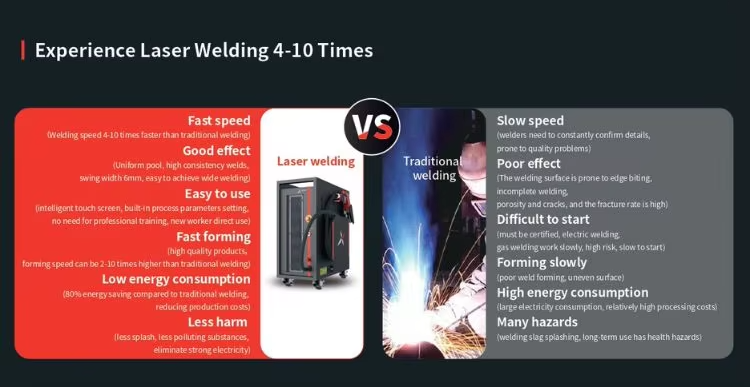

1. High photoelectric conversion efficiency

2. High output power and superior beam quality

3. High power stability, high reliability, and long service life

4. All fiber structure, compact, maintenance free, and low cost

5. Compared to traditional argon arc welding technology, laser welding has a greater heat fusion effect on thin plates, is prone to deformation, and is more troublesome in post-processing. Laser welding has a smaller thermal impact on thin plates, is less prone to deformation, and the weld bead is uniform and smooth, requiring almost no post-processing.

6. You can quickly learn how to operate, saving you expensive technical labor costs.

7. Processing is environmentally friendly, and red light positioning is used for handheld fiber optic head welding. The handheld processing head is lightweight, with high worker efficiency and less fatigue during long-term welding.

Weldable materials: stainless steel, carbon steel, brass, aluminum alloy, galvanized sheet, aluminum zinc plate, alloy steel, silicon steel plate, pickling plate, titanium alloy, manganese steel, etc.